Water usage is as necessary to Evaporative Cooling as electricity is to refrigeration. When discussing water usage, opponents of Evaporative Coolers, (Proponents of Refrigeration) often equate “Usage” to “Waste”. This could never be farther from the truth! Water is a resource like many others in that it is 100% renewable after use in an evaporative cooler. When the water is evaporated it leaves various solid compounds and elements such as calcium normally found in tap water in the cooler’s reservoir. That reservoir water is systematically purged and is perfectly fine to be used in watering your grass, garden, or trees. After evaporation it is not irrevocably changed and returns to nature quickly and cleanly unlike other resources such as Petroleum or Natural Gas. That being said, let’s discuss how water is used and managed in an evaporative cooler.

All evaporative coolers consume water via evaporation. This is what provides the cooling. The amount of water consumed by any given evaporative cooler can be expressed in a fairly simple equation. In order to begin understanding this concept, you must first understand a few relevant terms:

- Dry Bulb Temperature (Db): This is the ambient air temperature that surrounds you.

- Wet Bulb Temperature (Dw): This is lowest temperature the air can attain by evaporating water into the air.

- Wet Bulb Depression (∆T): This is the difference between the Dry Bulb and Wet Bulb temperature. (Db – Dw=∆T)

- Efficiency (eff): This is a ratio of the actual air temperature drop across the media compared to the Wet Bulb Depression, expressed as a decimal percentage. If the Wet Bulb Depression is 40 degrees and the actual temperature drop measured across the cooling media is 30 degrees, the cooling efficiency of the media is 75% (30/40 = .75). This cooling efficiency is also known as the “Saturation Efficiency” because it refers to the amount of moisture that the media can evaporate into the air.

- Cubic Feet per Minute (CFM): A number to express the volume and velocity of air movement.

- Gallons per Hour (GPH): A number to express volume and speed of water evaporated.

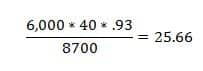

Now that we understand the terms, let’s examine the equation for the rate of evaporation.

The rate that water evaporates is affected by the speed the air is passing through the media, the actual wet bulb depression and the efficiency of the media itself. For illustration purposes we will choose the following conditions:

- Db=100°F

- Wb=60°F

- ∆T=40°F

- Eff=93% (.93)

- CFM=6,000

This is the water that is actually evaporated but does not account for the “Purge Water” that is evacuated from the reservoir to maintain a clean media section. Please note that these values are in “Run Time Hours” not total hours in a day.

“Purge Water” is another necessary use for water in an evaporative cooler. As discussed earlier, when water is evaporated, it leaves behind the solid particles that do not evaporate. These particles include, but are not limited to Calcium and various salts. These deposits, if left to collect in the system, can cause scaling and corrosion hence must be evacuated from the system periodically. There are a few methods commonly used to satisfy this need and a few innovations only available from our company. These methods are as follows:

- Bleed-Off: This method is one of the oldest and most common methods to reduce the buildup of minerals in the reservoirs. It is simply a capillary tube that allows a certain amount of water from the pump to be diverted from the media distribution assembly directly down the stand pipe drain. The rate of water typically relieved through this tube is 12oz/minute of cooler run time. Or approximately 720oz (5.625 Gal)/hour of cooler run time. Although this is a widely accepted method, its flaw is that it is difficult for the average homeowner to regulate this rate based on the size of their cooler or the hardness of their water; hence it is the least economic from a water usage standpoint and can use more water than actually required.

- Scheduled System Dump: This is another very common method used by most cooler manufacturers; however all “Scheduled Dump Systems” are NOT created equal and you will see a natural progression of innovations only available from our company.

- Timer Method: This method uses a timer to log the number of run time minutes and cycles a separate pump to run, after a predetermined run time, for a predetermined time period in an attempt to evacuate the reservoir. This method is used by many cooler & cooler parts manufacturers and is a more cost effective method than the “Bleed Off” method. It is more economical because it is not a constant bleed off and typically only evacuates the system once in an 8-hour period and then for only 7-minutes. At a flow rate of 4-Gal/minute, it only evacuates 28-Gal over an 8-hour period, OR 3.5-Gal/hour of cooler run time. This is a savings of 2.125-Gal as compared to the “Bleed-Off” method. This is an improvement, but still has some short comings. The problem with this method is in that although it is better than the “Bleed-Off” method, it still purges 28-Gal of water over a period of 8-hours of cooler run time.

- Programmable Drain System: This innovation, only available from our company, gives you the flexibility of selecting how often the system should purge and how long that purge should last. The frequency of how often the system should purge is based on the quality of the water supplied to the cooler. In areas with very hard water, the frequency of purging should be more frequent and less frequent where the water quality is better. Similarly, a small cooler may empty its reservoir in only 5-minutes where a larger cooler requires closer to 9-minutes to empty. Only our company gives you that flexibility with:

- Custom CleanTM (BDC100): This accessory turns your simple recirculation pump into a state of the art Programmable Drain System. Simply plug your current recirculation or “Primary” pump into the specially designed Custom Clean TM plug. Plug a secondary pump into the other end of the Custom Clean TM and hook its hose to the included hose adapter and to the cooler drain. This system will record the hours of cooler run time and cycle the secondary drain pump based on the frequency and run time selected by you. With this system you can select a clean frequency of 2, 4, 6, or 8-hours as well as select a drain run time of 5 or 9-minutes. This flexibility ensures that you are using water more wisely and purging your system only as required. An added bonus of this design is that you do NOT need two different types of pump! Two standard recirculating pumps perform both functions. This feature comes in handy in the event one pump fails and you are in a bind until you can get to the store to purchase a replacement. The primary pump is always the first to fail since it is used continually during the operation of the cooler while the secondary pump is only used during the purge cycle. Imagine a hot holiday party and your primary pump fails. Typically you would be without cooling until you replaced that pump. Since you have an identical pump as your secondary pump, you can simply switch pumps and get the cooler back on to keep the family gathering cool! The only drawback is you will not be able to drain the system until you replace that pump at least you remained cool until you could purchase a suitable replacement.

- Programmable Drain Pump (patent pending): This innovation released in 2014, takes all the features of the Custom Clean TM and incorporates it into the body of the pump itself. It even has a “Continuous Run” mode in the event you need to swap it out with your primary pump as with the Custom Clean TM.

- Programmable Drain Pump II (patent pending): This latest innovation is truly an intelligent water management system! Not only can this product be set to predetermined frequencies and run times with all the features of the Custom Clean TM, but it can accurately measure the actual percentage of harmful minerals in the reservoir and purge based the system based on those values. No more guess work!